LASER CLEANING SYSTEMS

Laser cleaning effectively removes surface contaminants using a precise laser beam.

We offer cleaning as a service or equipment rental with full support. Choose what suits you best.

What Services We Offer

**PURITY WITHOUT COMPROMISE – LASER TECHNOLOGY FOR A PERFECT RESULT**

WHAT PURPOSES CAN A CLEANING LASER BE USED FOR?

Laser cleaning is a modern and effective technique that allows the removal of various types of contaminants and layers from many materials without damaging their surface. This method is widely used in both industry and art conservation for the following purposes:

RUST AND CORROSION

Effective removal of rust and corrosion products from metal surfaces.

OXIDATION LAYERS

Cleaning metals from oxides, such as aluminum or copper.

PAINTS AND COATINGS

Removal of old coatings and paints from various materials.

ADHESIVES AND ADHESIVE RESIDUES

Removal of adhesives without damaging the underlying material.

ORGANIC CONTAMINANTS

Cleaning grease, oils, and biological deposits.

GRAFFITI

Gentle removal of graffiti from stone and concrete surfaces.

WELDING RESIDUES

Cleaning welds and removing welding residues.

ELECTRICAL COMPONENTS

Removal of oxidation layers from sensitive electronic components.

CARBON COMPOSITES

Cleaning carbon fiber surfaces without damaging their integrity.

ADVANTAGES OF CLEANING LASERS

ENVIRONMENTAL FRIENDLINESS

Laser cleaning does not use chemicals, reducing the production of hazardous waste.

MATERIAL-FRIENDLINESS

Unlike blasting and sandblasting, the surface of the cleaned material remains undamaged.

PRECISION

Laser beams enable detailed and precise cleaning of even small parts.

NON-ABRASIVENESS

Does not cause tool wear and is suitable for delicate components.

SPEED

Rapid removal of contaminants shortens downtime and increases productivity.

COST/EFFECTIVENESS

Laser cleaning offers an excellent cost-performance ratio due to its efficiency and low operating costs, ensuring top-quality cleaning at a reasonable price.

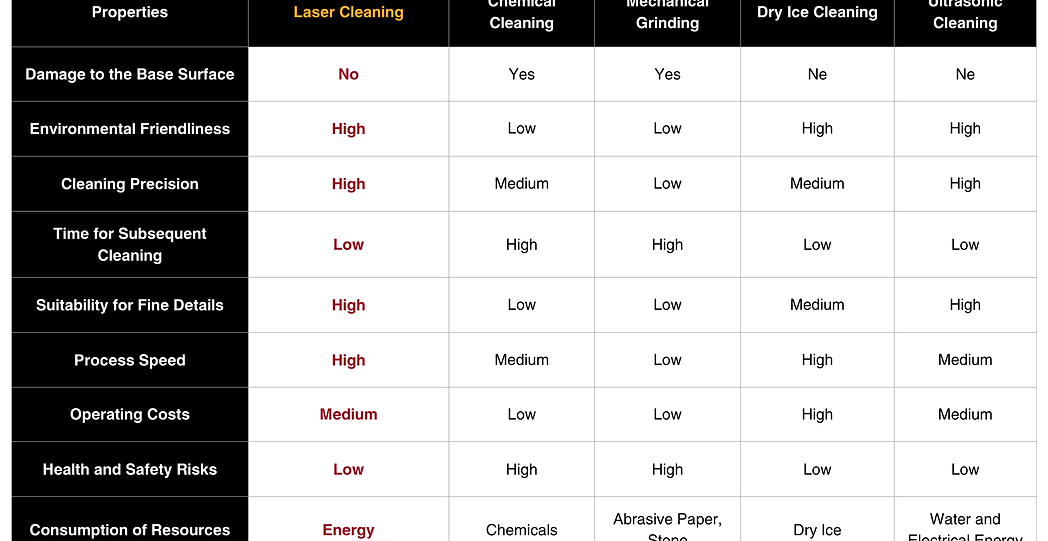

LASER CLEANING: A MORE EFFICIENT SOLUTION COMPARED TO DRY ICE CLEANING

Modern laser technology is revolutionizing cleaning—it's gentle, efficient, and eco-friendly. Unlike dry ice cleaning, it offers precise contaminant removal without abrasive effects or high maintenance costs. It also reduces the risk of condensation and moisture, ensuring longer durability of cleaned surfaces...

CLEANING METHODS - COMPARISON

HOW CLEANING IS PERFORMED

Laser cleaning works by focusing a laser beam on surface contaminants, gradually vaporizing them. During this process, the material is transformed into vapor and plasma, which are subsequently removed. The cleaned area is left free of contaminants and ready for further processing. This method is efficient and precise, ensuring high-quality surface cleaning.

OUR PARTNERS